Intel has officially inaugurated Fab 9, a state-of-the-art manufacturing facility located in Rio Rancho, New Mexico, marking a significant milestone in semiconductor technology. This opening is part of Intel’s previously announced $3.5 billion investment in its New Mexico operations, aimed at equipping the site for advanced semiconductor packaging technologies. This includes Intel’s groundbreaking Foveros 3D packaging technology, designed to combine multiple chips for optimized power, performance, and cost efficiency.

Keyvan Esfarjani, Intel executive vice president and chief global operations officer, stated, “Today, we celebrate the opening of Intel’s first high-volume semiconductor operations and the only U.S. factory producing the world’s most advanced packaging solutions at scale. This cutting-edge technology sets Intel apart and gives our customers real advantages in performance, form factor and flexibility in design applications, all within a resilient supply chain.” He also congratulated the New Mexico team and partners for their relentless pursuit of packaging innovation.

This development is pivotal for several reasons. Intel’s global factory network is a critical competitive asset, enhancing product optimization, economies of scale, and supply chain resilience. Fab 9 and the co-located Fab 11x in Rio Rancho are the first operational sites for the high-volume manufacturing of Intel’s advanced 3D packaging technology. This co-location establishes an efficient end-to-end manufacturing process, streamlining the supply chain from initial demand to the final product.

Aerial view of Intel's Fab 9 industrial complex in Rio Rancho, New Mexico, showcasing buildings, pipes, and cranes against a clear sky and mountain backdrop.

Aerial view of Intel's Fab 9 industrial complex in Rio Rancho, New Mexico, showcasing buildings, pipes, and cranes against a clear sky and mountain backdrop.

Fab 9 is poised to be a major driver for the next wave of innovation in advanced packaging technologies at Intel. As the semiconductor industry increasingly adopts heterogeneous integration, using multiple “chiplets” within a single package, advanced packaging solutions like Foveros and EMIB (embedded multi-die interconnect bridge) become increasingly crucial. These technologies offer a quicker and more cost-effective route to achieving the ambitious goal of 1 trillion transistors on a chip, effectively extending Moore’s Law beyond 2030.

Foveros, Intel’s innovative 3D advanced packaging technology, is a pioneering solution that allows for the creation of processors with compute tiles stacked vertically, rather than the traditional side-by-side arrangement. This vertical stacking capability provides Intel and its foundry clients with the flexibility to mix and match compute tiles, optimizing both cost and power efficiency for diverse applications.

New Mexico Governor Michelle Lujan Grisham highlighted the broader impact of this investment, stating, “This investment by Intel underscores New Mexico’s continued dedication to bring manufacturing back home to America. Intel continues to play a key role in the state’s technology landscape and strengthen our workforce, supporting thousands of New Mexico families.”

The $3.5 billion investment in Rio Rancho has already generated significant economic benefits for the region, creating hundreds of high-tech jobs at Intel, over 3,000 construction jobs, and an estimated 3,500 additional jobs across the state.

Ribbon-cutting ceremony for Intel Fab 9 in Rio Rancho, New Mexico, featuring Keyvan Esfarjani, local officials, and Intel managers celebrating the facility opening.

Ribbon-cutting ceremony for Intel Fab 9 in Rio Rancho, New Mexico, featuring Keyvan Esfarjani, local officials, and Intel managers celebrating the facility opening.

Intel’s commitment to New Mexico extends beyond economic investment to environmental responsibility and community engagement. Fab 9 is designed to minimize its environmental impact, targeting at least 90% recycling of construction waste, a goal consistently surpassed in recent months. Furthermore, Intel is committed to using 100% renewable electricity for its New Mexico operations.

The company has also invested in water restoration projects in New Mexico watersheds, funding three nonprofit initiatives estimated to restore over 100 million gallons of water annually. These projects enabled Intel to return and restore over 100% of its water usage in New Mexico in 2022. Additionally, Intel’s water conservation efforts at its New Mexico site saved over 500 million gallons of water, equivalent to the annual water consumption of over 4,500 U.S. households.

Intel’s history in Rio Rancho dates back to 1980, with a cumulative investment exceeding $16 billion. Beyond business operations, Intel actively participates in the local community. In the last five years, Intel employees have volunteered over 65,000 hours in New Mexico. Moreover, Intel, the Intel Foundation, and Intel employees have contributed more than $6.5 million to local nonprofits and schools since 2018. This includes establishing endowment scholarships at five New Mexico colleges and universities, supporting workforce development and education through internships and STEAM programs.

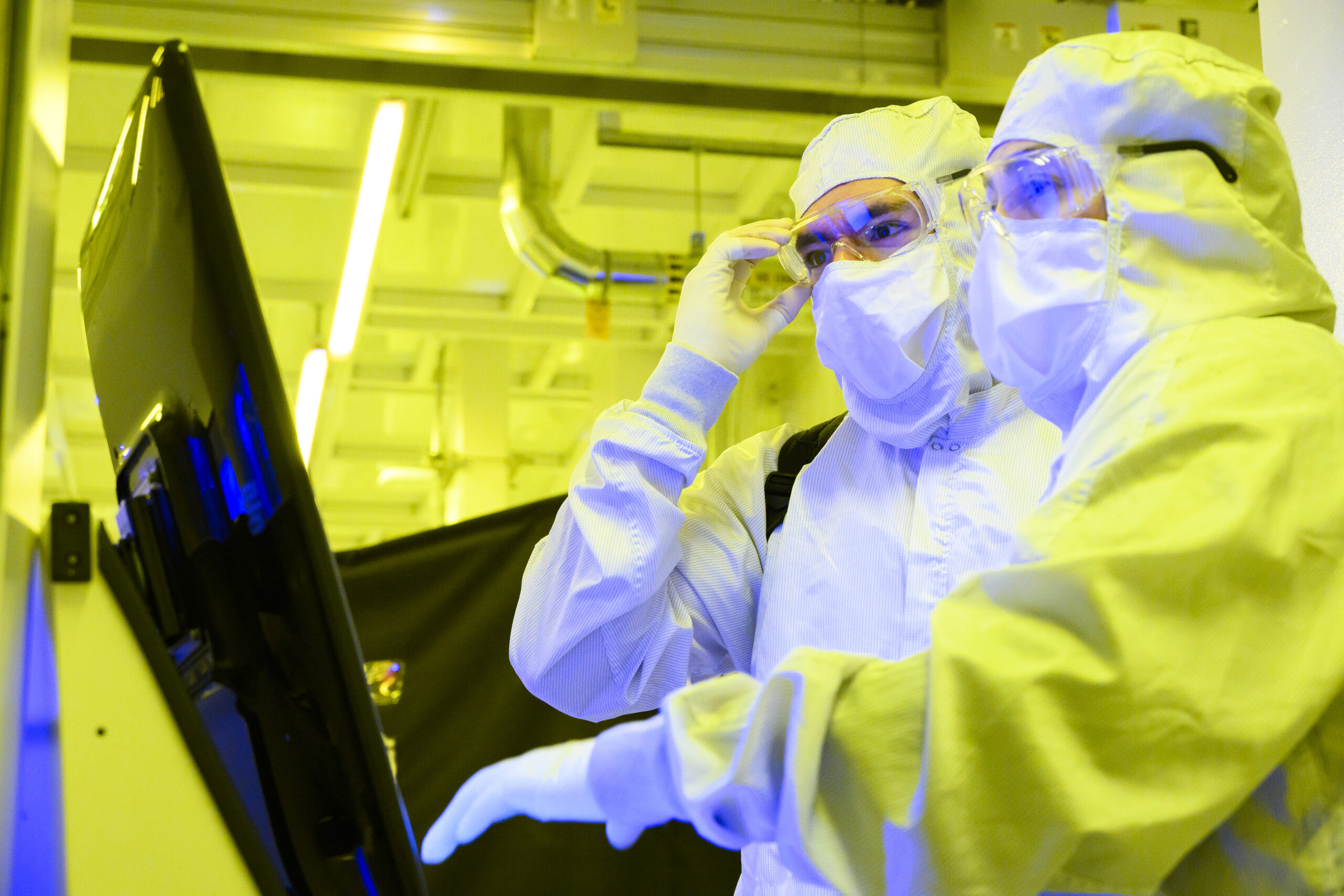

Manufacturing technicians in cleanroom attire work with equipment in Intel's Fab 9, Rio Rancho, New Mexico, under yellow lighting, focusing on advanced semiconductor processes.

Manufacturing technicians in cleanroom attire work with equipment in Intel's Fab 9, Rio Rancho, New Mexico, under yellow lighting, focusing on advanced semiconductor processes.

The opening of Fab 9 in Rio Rancho signifies not just an expansion of Intel’s manufacturing capabilities, but also a deepened commitment to innovation, U.S. manufacturing, and the New Mexico community. This facility is set to play a crucial role in advancing semiconductor technology and bolstering Intel’s leadership in the global market.

Intel technician in a cleanroom suit inspecting advanced packaging equipment at Fab 9, Rio Rancho, New Mexico, emphasizing precision and technological advancement.

Intel technician in a cleanroom suit inspecting advanced packaging equipment at Fab 9, Rio Rancho, New Mexico, emphasizing precision and technological advancement.

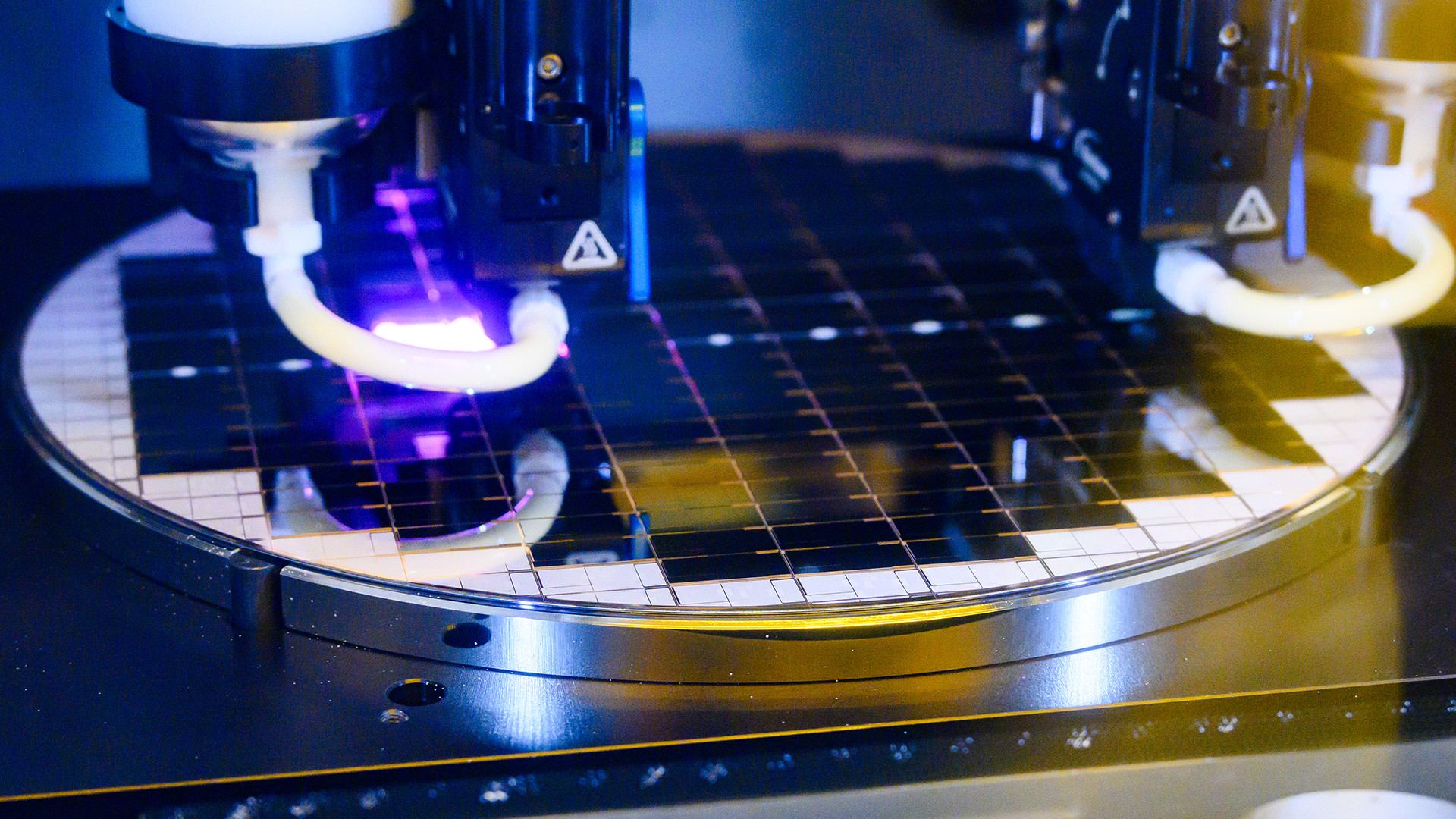

Close-up of chiplet bonding within advanced packaging technology Foveros at Intel's Fab 9, Rio Rancho, New Mexico, showcasing intricate processes and precision machinery.

Close-up of chiplet bonding within advanced packaging technology Foveros at Intel's Fab 9, Rio Rancho, New Mexico, showcasing intricate processes and precision machinery.

Robotic arm handling a silicon wafer in the automated manufacturing environment of Intel's Fab 9, Rio Rancho, New Mexico, highlighting automation in semiconductor production.

Robotic arm handling a silicon wafer in the automated manufacturing environment of Intel's Fab 9, Rio Rancho, New Mexico, highlighting automation in semiconductor production.

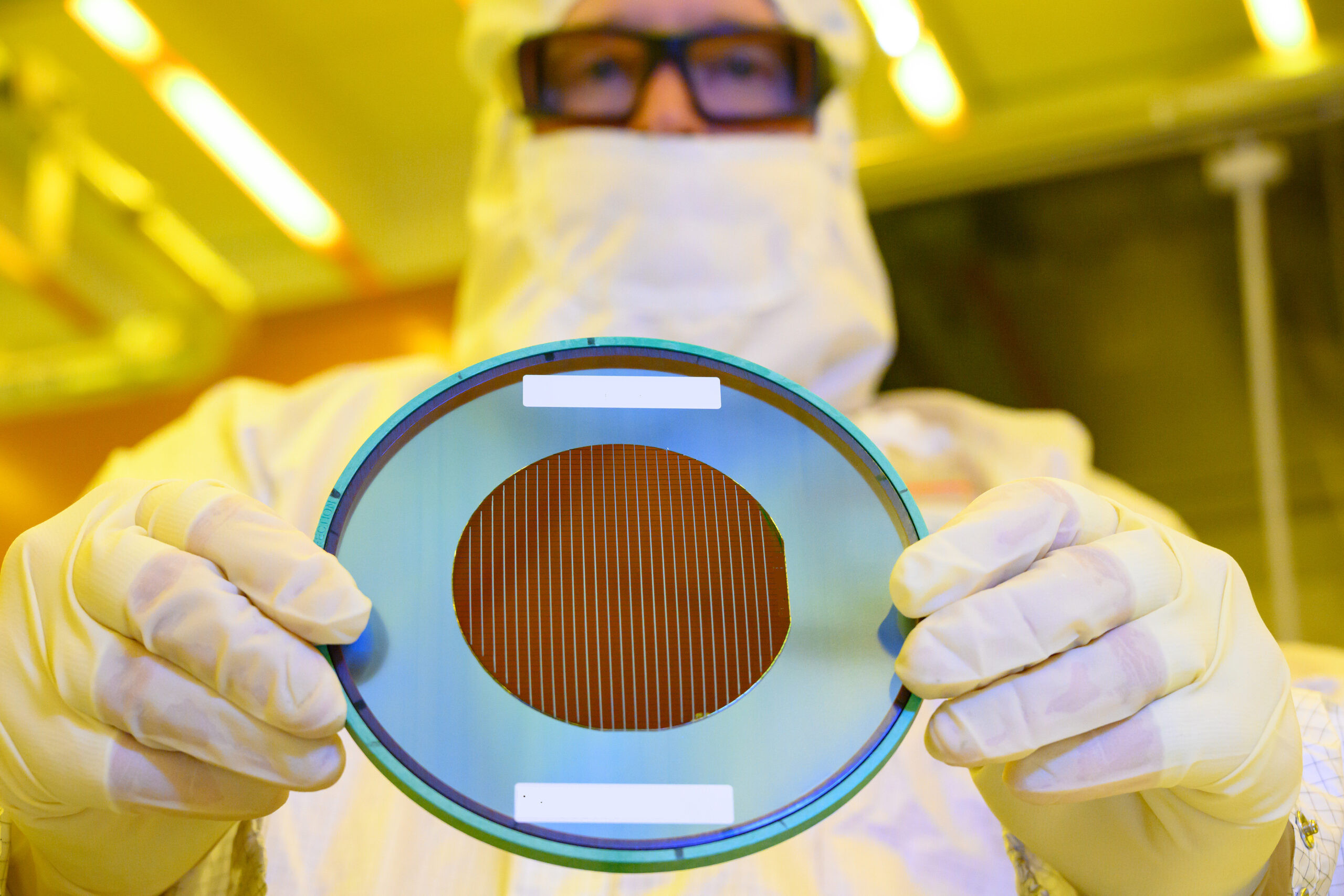

Technician holding a silicon wafer in a cleanroom at Intel New Mexico, displaying the advanced materials and technology in semiconductor manufacturing.

Technician holding a silicon wafer in a cleanroom at Intel New Mexico, displaying the advanced materials and technology in semiconductor manufacturing.